Fibre Services

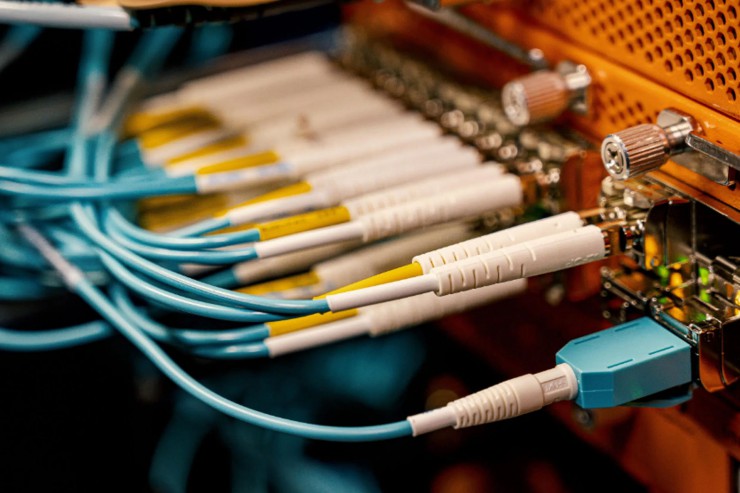

Our fiber optic engineers carry out the installation, testing, and maintenance of fiber optic systems using fusion splicing of single and multimode fiber optic cables. They have experience of blown fiber and FTTH installations and can read SL drawings. We pride ourselves on great customer service with health and safety a priority.

Our formula for successful and timely installation are:

– Top Class-skilled personnel

– Dedicated Project Manager per case

– 100% Quality tested stock of fiber optic products

– Predefined Operational ISO9001 Quality procedures

-quality service level agreements (SLAs) including technical support 24×7

Our Installation capabilities include Fibre-to-the-Home, Aerial, Hand drop-Hand dig, and Fiber Termination.

a. Fiber to the Home (FTTH)

Fiber to the home (FTTH) is an access network architecture that allows deploying xPON technology to provide the highest possible speeds of Internet access downstream (from the network to the end-user) as well as upstream (from the user to the network) over optical fiber from the operator’s switching equipment to an individual home. Fiber reaches directly the home of the end-user.

At Routersec Technologies, we are aware of technological change and the speed with which the telecommunications market evolves. Therefore, we offer programmed resources for equipment changes and specialized personnel to provide on-site support by providing installation or maintenance of any device, guaranteeing:

- The ability to provide much higher two-way transmission speeds, which delivers a multitude of digital information — telephone, video, data, etc. — more efficiently. Fiber has virtually unlimited capacity with bandwidth upgrades just limited by the state-of-the-art of active equipment.

- Cost reduction of FTTH components and equipment (fiber, splicing boxes, splitters, drop, OLT, ONTs, etc.) over the last years

- Maintenance costs are also reduced as there is no active equipment in the field requiring service and optical components are extremely reliable. Network operation and maintenance are simpler by using full automation and software control.

- The lifespan of the fiber optic cable (30+ years). Not affection by electromagnetic interference, which is a source of downtime in copper networks.

b. Aerial Cable Installation

Deploying fiber above ground on poles or towers removes the need for underground digging and is particularly useful when the ground is uneven, rocky, or both. Aerial installation is generally much less costly than underground construction also.

The fiber in a duct solution has a major aesthetic advantage; once installed, they are invisible, leaving no mark on the landscape. Unlike aerial installations, they are less affected by most adverse weather like high winds or freezing rain. But underground installations can be vulnerable to flooding damage.

However, there are a number of reasons for choosing an aerial solution, such as:

- Aerial fibers are typically much faster and cheaper to deploy than buried networks.

- The planned route may be undulating, rocky, or both, making digging less appealing.

All-Dielectric Self Supporting (ADSS) cables can be erected in close proximity to power transmission lines. This, of course, allows for pole sharing, which of course, reduces installation costs and speeds-up deployment.

Before beginning aerial installations, the design of the cable plant must be properly done and checked. Routes must be surveyed, ground conditions tested, and all components procured and received. Permits from local authorities must be obtained and coordination with local agencies such as traffic and police must be properly planned.

If poles exist already, it is required to have proper permits for adding communications cables and the poles must be “made ready” by the owner of the poles are authorized parties. This may take considerable time which must be factored in the planning of the project. Sometimes lightweight fiber cable may be lashed to previously installed cables such as older copper phone cables or CATV hardline coax, but proper permissions must be obtained.

Prior to installation, the location of splice points and storage of slack cables must be determined and noted in the design. Splice locations should be chosen with the need for parking a splice truck, van, or trainer nearby.

c. House Drop Installation

- TRENCHING METHOD

The two most popular methods to install fiber-optic cables are Micro Trenching and Narrow Trenching.

This allows Micro-ducts to safely and quickly be laid with minimal disruption to the infrastructure. Micro-ducts are placed directly into a trench in existing asphalt, concrete, modular, block paved or soft infrastructure. Which solution is optimal for you depends on your fiber-optic requirements and municipal regulations. Telco-approved access chambers can be installed along the designated route, or existing handholes and/or manholes can be incorporated into the network.

- MICRO TRENCHING

A Micro Trench installation is fast, affordable, and non-invasive, perfect for cost-efficient projects and municipalities where a shallow installation is acceptable. We recommend a depth of no less than 30 cm in hard deployments or 25 cm of depth in soft infrastructure, but pre-defined municipal standards are always taken into account.

- NARROW TRENCHING

The Narrow Trench installation is deeper and wider, where municipalities require a greater depth or where terrain conditions require. The width of any trench depends on the Micro-duct configuration and the strand count requirement, usually between 6 cm & 15 cm. Narrow Trenching is commonly used for backbone fiber applications and utility installations.

d. Fiber Termination

Fiber cable termination is the addition of connectors to each optical fiber in a cable. The fibers need to have connectors fitted before they can attach to other equipment. Two common solutions for fiber cable termination are pigtails and fanout kits or breakout kits.

We terminate fiber optic cable two ways - with connectors that can mate two fibers to create a temporary joint and/or connect the fiber to a piece of network gear or with splices that create a permanent joint between the two fibers. These terminations must be of the right style, installed in a manner that makes them have little light loss and protected against dirt or damage in use.

FIBRE OPTICS TOOLS & EQUIPMENT

- Precision Fiber Cleavers

- Electrical Cutting, Crimping, & Hand Tools

- Crimp Tools

- Kevlar Shears & Cutters

- Strippers & Slitters

- Electrical Work Bench Tools

- Scribes

- Epoxy Curing Ovens & Equipment

- Ladder

- Corning Fibre kit

- Wilton Thinline Trenching Spade.